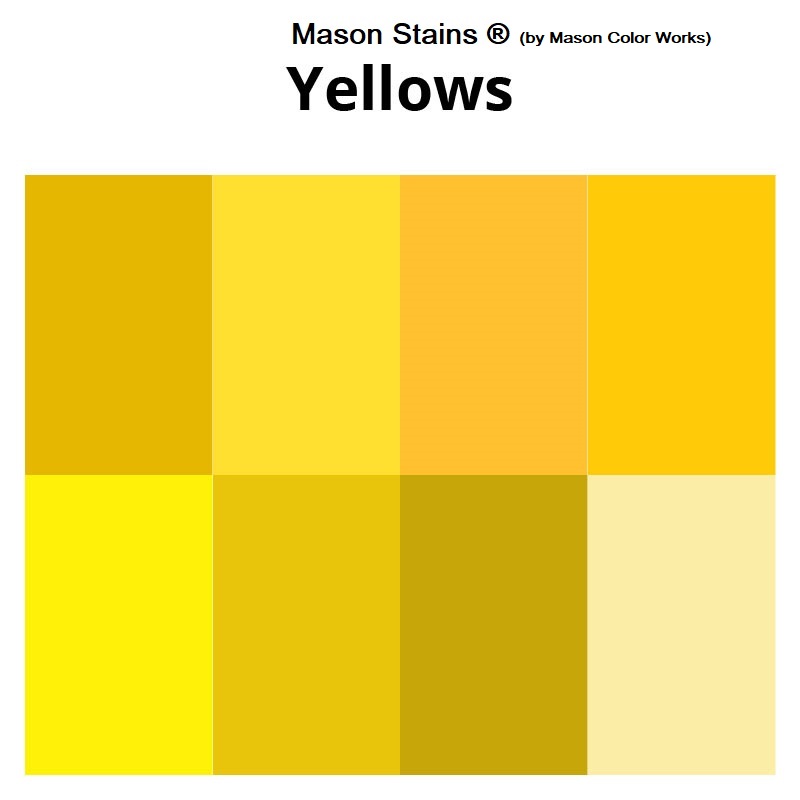

Mason Stains®(by Mason Color Works): Yellows

December 22, 2016

Shimpo Slab Roller 30X50

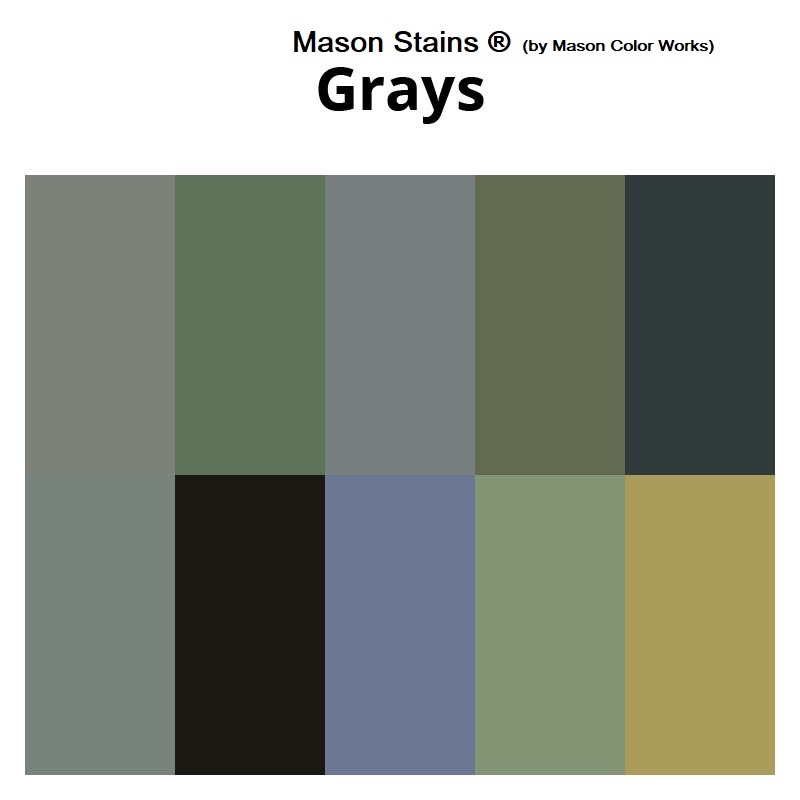

December 29, 2016Mason Stains®(by Mason Color Works): Neutrals, Blacks and Whites

$4.85 – $218.30

Mason Stains® (by Mason Color Works) Ceramic Stains

Definition of a Stain: A stain is essentially an oxide or series of oxides and opacifiers which have been blended together, calcined (or fired), then ground to a 200 or so mesh powder. The reasons for using a stain versus an oxide, etc. are (1) Stability of Color — an important criteria for wall tiles, sanitary ware, etc. (2) Insolubility — an insoluble (in water) stain greatly diminishes the risk in handling wet glazes when dipping or pouring, etc. (3) Color — the fired color of most stains is identical to the raw color because it has already been fired. It is, therefore, easier to use or to mix to achieve another color. It can also be mixed with a variety of medium to turn them into china paints, enamels, silk screen colors, decals, etc.

Key to Composition Chart

- Al Aluminum oxide Al2O3

- B Boric oxide B2O3

- Ca Calcium carbonate CaO3

- Co Cobalt oxide CoO

- Cr Chromium oxide Cr2O3

- Fe Iron oxide Fe2O3

- Mn Manganese dioxide MnO2

- Ni Nickel oxide NiO

- Pb Lead oxide PbO

- Pr Praseodymium oxide Pr6O11

- Sb Antimony dioxide Sb2O3

- Si Silicon dioxide SiO2

- Sn Tin dioxide SnO2

- Ti Titanium dioxide TiO2

- V Vanadium oxide V2O5

- Zn Zinc oxide ZnO

- Zr Zirconium dioxide ZrO2

Reference Notes

1. Can be used as body stain in porcelain at high temperatures.

1a. Use only as body stain.

Firing temperatures can only be a rough guide. Firing at 2200°F on a slow schedule may give the equivalent maturing as firing at 2300°F on a fast schedule. The cycle, atmosphere, and rate of cooling will affect the color.

2. Max. firing limit 2156°F (1180°C)

3. Max. firing limit 2390°F (1310°C)

4. Max. firing limit 1976°F (1080°C)

Zinc oxide influences the color in a glaze more than any other element. Generally, zincless glazes should contain no magnesium oxide. Some colors containing zinc are to be used in a zincless glaze. The zinc in the color is in a combined form and will not harm the color, but free zinc oxide in the glaze can destroy the color.

5. Do not use Zinc in the glaze.

6. May be used with zinc or without zinc.

7. Zinc not necessary but gives better results.

8. Best results with no zinc.

Calcium oxide content as calcium carbonate should be between 12-15% for best color development. Adding the molecular equivalent of calcium oxide with Wollastonite, a natural calcium silicate, often gives better uniformity. The increased silica from the Wollastonite must be subtracted or the glaze will have a poor surface.

9. Glaze must contain 6.7 to 8.4% Calcium Oxide.

Notes by Mason Stains® (by Mason Color Works) – You must test under your conditions.

| 1# | 5# | Reference | ||||

|

6700 |

White | ZrAlSi | 4.85 | 15.52 | $62.06 | 3,6 |

| 6768 | Tin White | SnAlSi | 17.05 | 54.58 | 218.30 | 3,6,8 |

| Weight | N/A |

|---|---|

| Stain Color | 6500 Sage Grey, 6503 Taupe, 6506 Pearl, 6527 Shadow, 6528 Charcoal, 6530 Silver, 6537 Mouse Grey, 6540 Blue Grey, 6572 Neutral Grey, 6573 Rose Taupe, 6591 Gun Metal, 6600 Black, 6601 Velvet, 6609 Black, 6612 Onyx, 6650 Black / Cobalt Free, 6657 Black, 6666 Black / Cobalt Free, 6700 White, 6768 Tin White |

| Quantity | 1/4 lb., 1 lb., 5 lbs. |